Beyond Efficiency. Engineered TCO.

We provide more than just a machine; we deliver a meticulously engineered

TCO Blueprint™ for predictable savings and performance.

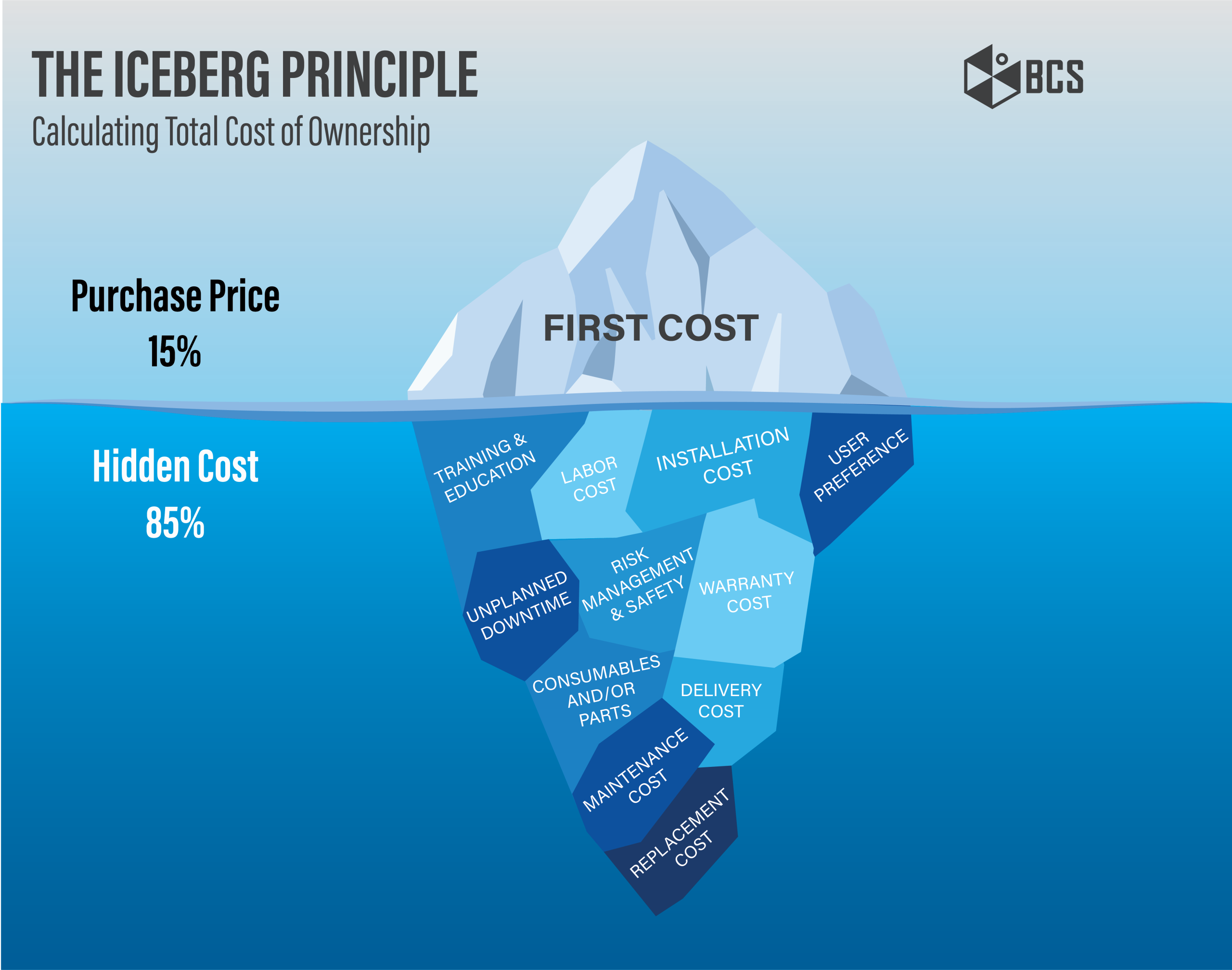

The Hidden Costs Sinking Your Budget?

The initial purchase price is just the tip of the iceberg. What truly impacts your total cost

of ownership (TCO) are the massive, hidden costs beneath the surface.

The TCO Iceberg

The initial purchase price is just the tip of the iceberg. What truly impacts your total cost of ownership (TCO) are the massive, hidden costs beneath the surface.

- Energy Costs (75–80%): $40,000 over 5 years

- Maintenance: $5,000 over 5 years

- Downtime Loss: $15,000 over 5 years

- Total 5-Year Cost: $70,000+

Introducing The TCO Blueprint

Your Path to Predictable Savings. We’ve re-engineered the air compressor from the ground up, focusing on the three pillars of Total Cost of Ownership.

AeroFlow Dynamics Airend

Revolutionary screw profile and housing design minimize pressure drop and turbulence, converting more energy directly into compressed air. Up to 15% more efficiency than standard designs.

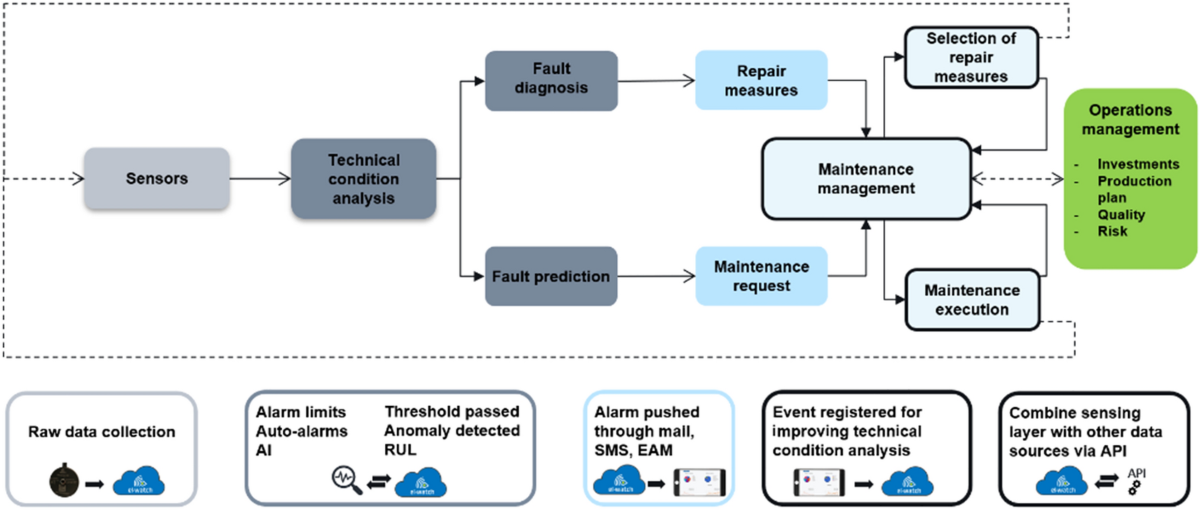

DuraSense Predictive Sensors

Embedded sensors monitor critical components for vibration, temperature, and wear in real-time. Alerts you to potential issues before they cause failure, turning expensive downtime into predictable maintenance.

AdaptiDrive VSD Controller

Smart controller uses machine learning to analyze air demand patterns and precisely adjusts motor speed. Eliminates high electricity spikes of fixed-speed startups.

Why choose seize air?

Two-Stage Compression

Divides compression into two stages with intercooling, reducing temperature rise and internal leakage. Improves volumetric efficiency by 15-22%.

IE4/IE5 Permanent Magnet Motors

High-efficiency motors (up to 97%) maintain performance at partial loads. Integrated motor-air-end designs eliminate transmission losses.

Dual-VFD Intelligent Control

Twin variable frequency drives (main motor + fan) enable 25-100% speed modulation. Maintains constant pressure (±0.01MPa) and temperature (80-85°C), saving 15% energy.

Pressure Customization

Patented systems adjust output pressure to exact requirements. Reducing pressure by 1 bar saves 7% energy by avoiding over-compression.

Advanced Thermal Management

Oversized coolers with anti-fouling coatings operate at 52°C ambient temperatures. Centrifugal fans ensure uniform heat dissipation, reducing cooling energy by 3%.

Low-Friction Design

Precision-machined rotors (radial runout ≤2μm) with optimized profiles minimize internal leakage. Large-diameter piping and oil separators cut flow resistance, saving 3% energy.

Smart Air Intake Systems

Donaldson nano-filters with pre-cooling cyclones ingest colder external air. Double filtration extends component life while improving volumetric efficiency by 1.5%.

IoT Optimization

Touchscreen PLC controllers with real-time monitoring (pressure/temperature/flow) enable predictive maintenance. Cloud connectivity prevents efficiency degradation through timely interventions.

Precision Manufacturing

German KAPP grinders and Japanese Okuma centers ensure rotor tolerances of ±3μm. SKF bearings and Saint-Gobain seals minimize mechanical losses.

Cumulative Impact

These technologies deliver 30-40% lower energy consumption versus conventional compressors, with TÜV-certified performance. Lifecycle analysis shows electricity costs account for 90% of total ownership expenses – making Seize Air’s efficiency critical for operational ROI.

Company introduction

Reliable Performance in Industrial Environments

Engineered for continuous operation in demanding industrial settings, our compressors deliver consistent performance with minimal maintenance requirements.

- Robust construction withstands harsh conditions

- Smart monitoring system provides real-time diagnostics

- Modular design allows for easy maintenance and upgrades

The Proof is in the Numbers

See The Blueprint in Action. Calculate your potential savings with our interactive TCO tool.

| Metric | Your Current Compressor (Estimated) | Our Patented Compressor | Annual Savings |

|---|---|---|---|

| Annual Energy Cost | $50,000 USD | $38,500 USD | $11,500 USD |

| Annual Maintenance Cost | $5,000 USD | $2,500 USD | $2,500 USD |

| Annual Downtime Loss | $10,000 USD | $500 USD | $9,500 USD |

| Total Annual Cost | $65,000 USD | $41,500 USD | $23,500 USD |

Request a free, no-obligation TCO Analysis Report customized for your specific operational needs.

English

English

Russia

Russia

France

France

Spain

Spain

Arab

Arab