Dry two-stage oil-free screw air compressor

Working Pressure :

7.5-10.5[ bar ]- 109-152[ psig ]

Air Delivery :

161-2526[ cfm ]- 4.52-70.72[ m3/min ]

Working Power :

37-355[ kw ]- 57-466[ hp ]

×

- Product Details

- Technical Parameters

Dry two-stage oil-free screw air compressor features and advantages:

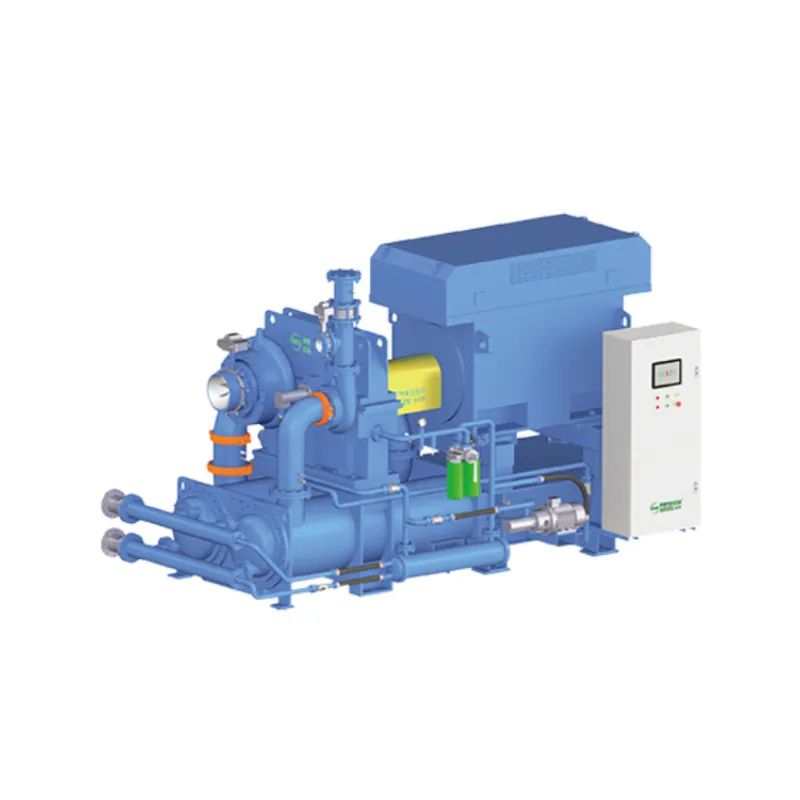

- The main engine adopts a double labyrinth seal structure, and an atmospheric opening hole is added between the two seals. This is a mature and stable sealing structure that can ensure that the air will not come into contact with the lubricating oil during the compression process, thereby ensuring that the compressed air discharged by the air compressor is 100% oil-free.

- Obtained ISO8573-1:20100 oil-free certification, which can meet the harsh application occasions including food and beverage, pharmaceuticals, petrochemicals, semiconductors, electronic products, medical, automotive painting and textiles, where oil is not allowed in compressed air.

- The main engine is designed according to the maximum intake temperature of 52℃, and the casing is equipped with a cooling jacket structure, which can effectively reduce the operating temperature of the main engine and can operate stably under very harsh environmental conditions; the transmission system adopts AGMA13-level speed increase gears and synchronous gears, SKF high-precision bearings, which can improve transmission efficiency and reduce noise, ensuring the smooth and reliable operation of the main engine.

- The rotor surface is coated with a layer of molybdenum disulfide coating through a special process, which can play the role of high temperature resistance, corrosion resistance, and impact resistance, which can effectively protect the rotor and improve the service life and compression efficiency of the main engine.

- The whole machine adopts a partition design to effectively isolate the high temperature area from the low temperature area. Both the compressed air intake and the cooling air intake use external independent air inlets to ensure the intake of air with lower external temperature.

- The enlarged cooler and gas pipeline system can control the pressure loss at a very small level, which can reduce the internal pressure loss and improve the efficiency of the whole machine compared with the ordinary structure.

- The cooler adopts the classic heat exchanger structure with water inside the pipe and gas outside the pipe, which can not only ensure that there is enough heat exchange area on the gas side, but also control the cooling water flow rate within a reasonable range, effectively improve the cooling effect, and make later maintenance more convenient.

- The frequency converter adopts IPM permanent magnet motor. Compared with ordinary three-phase asynchronous motors, the energy efficiency will not decrease with the decrease of speed, and the best motor efficiency can be maintained in the full speed range.

- The large-capacity cyclone steam-water separator is used to effectively remove condensed water from the compressed air, protect the second-stage main engine rotor, and extend the service life of the main engine.

- The large LCD screen can display the various operating parameters of the air compressor in real time; the modular PLC controller has excellent anti-interference ability, which meets the air compressor operation control and alarm and interlocking protection; the standard Modbus interface can realize DCS remote monitoring.

- Configured with the Sazhen Internet of Things system, the air compressor operation status, operation data, fault warning and other information can be displayed on site, mobile phone, and computer at the same time, and the air compressor status can be checked anytime and anywhere, which can better escort users to stable production.

01. Zero Oil Guarantee

02. Efficient and reliable main engine

03. Excellent whole machine design

04. Powerful control system

Application fields:

- Electronic semiconductor industry

- Pharmaceutical industry

- Food and beverage industry

- Chemical industry

- Automotive industry

- New energy industry, etc.

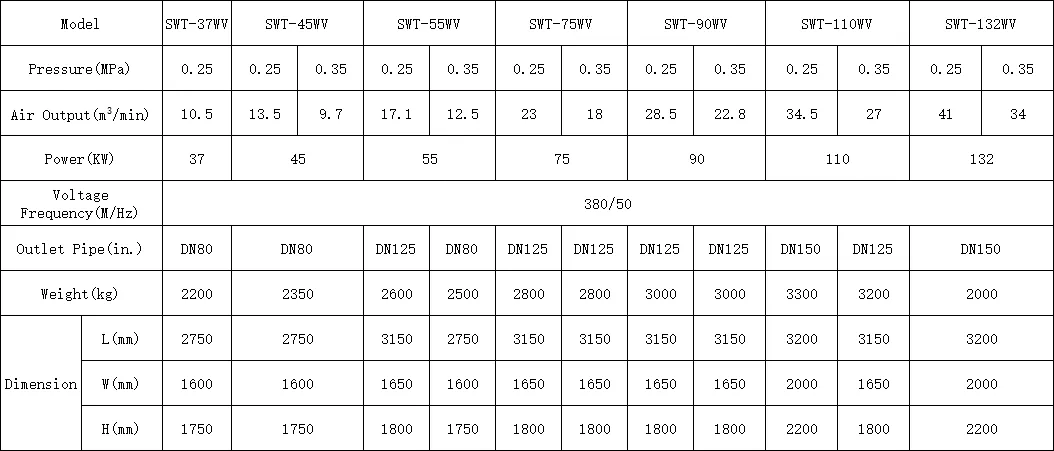

SWT-37WV-132WV

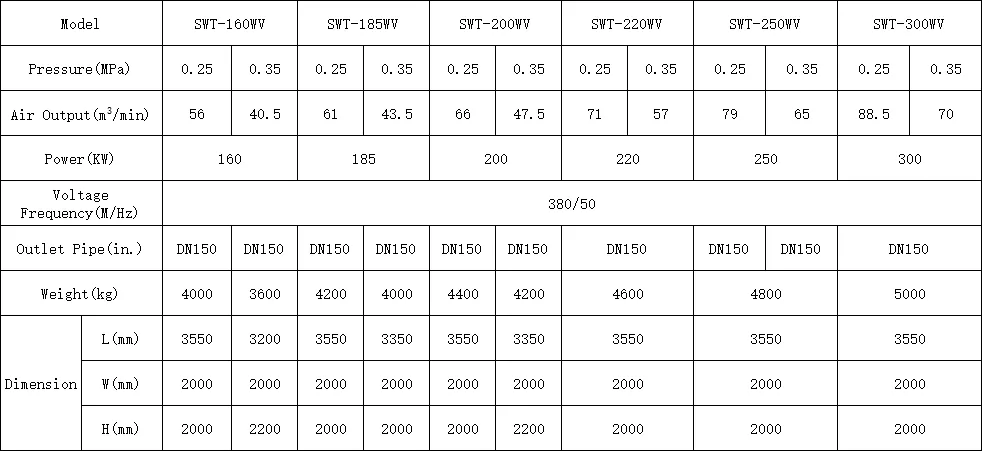

SWT-160WV-300WV

You may Like:

Energy Savings Calculator

Annual Savings

USD 0

* Based on 30% energy efficiency improvement from SEIZE technology

Save up to 30% energy with SEIZE compressors

Explore cutting-edge energy-efficient solutions

English

English

Russia

Russia

France

France

Spain

Spain

Arab

Arab