Magnetic levitation centrifugal energy-saving air compressor

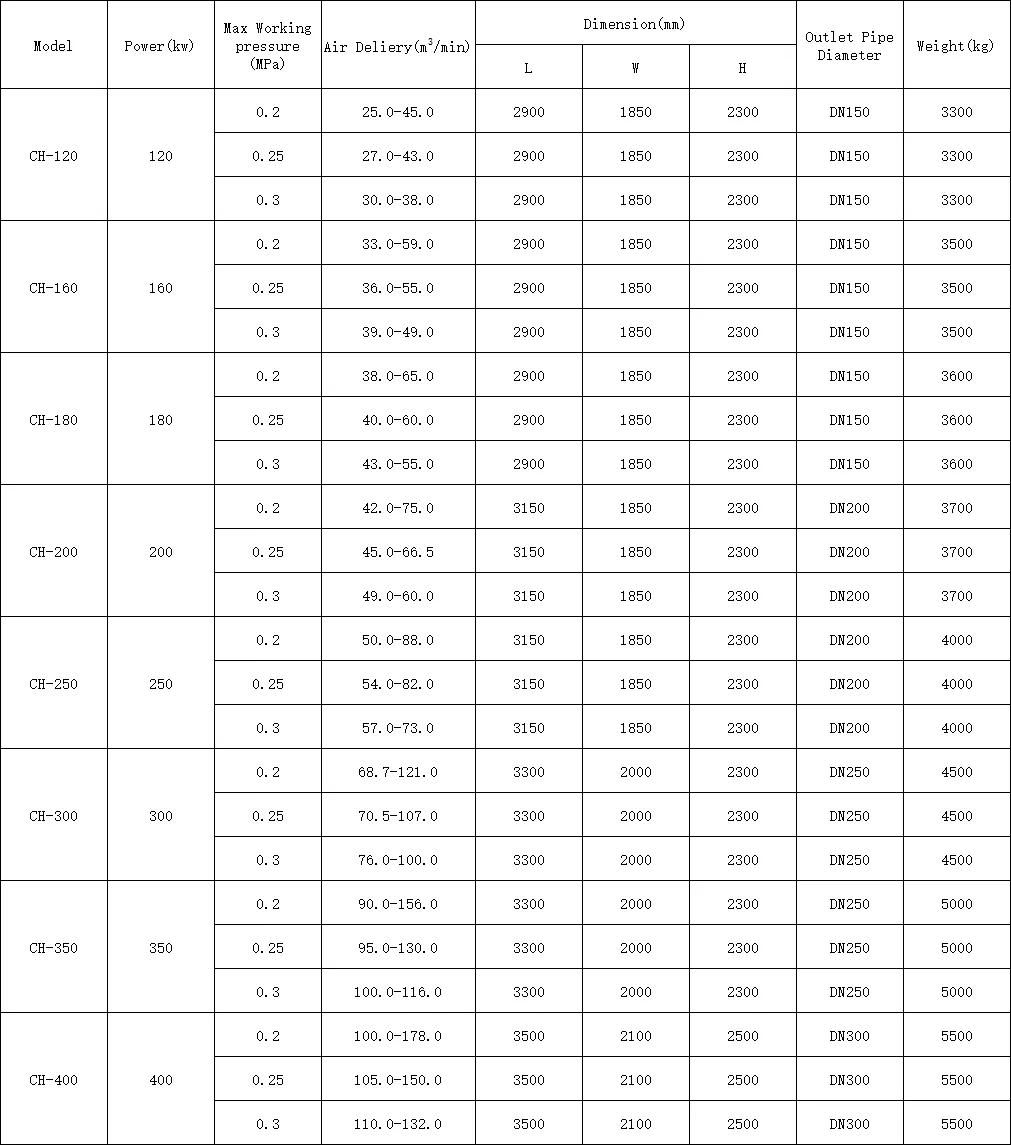

Working Pressure :

2-3[ bar ]- 29-44[ psig ]

Air Delivery :

893-4929[ cfm ]- 25-138[ m3/min ]

Working Power :

120-400[ kw ]- 160-540[ hp ]

×

- Product Details

- Technical Parameters

Magnetic levitation centrifugal energy-saving air compressor features:

- Adopting a three-stage filtration system, the filtration accuracy increases step by step.

- It can effectively prevent excessive dust from entering the host system and increase the service life of the host.

- The host directly inhales air from the environment, and the inhalation temperature is equal to the ambient temperature, which improves the efficiency of the whole machine.

- A variety of gas guide plates and built-in air filter elements are set at the air inlet of the host to effectively reduce the noise of the air inlet.

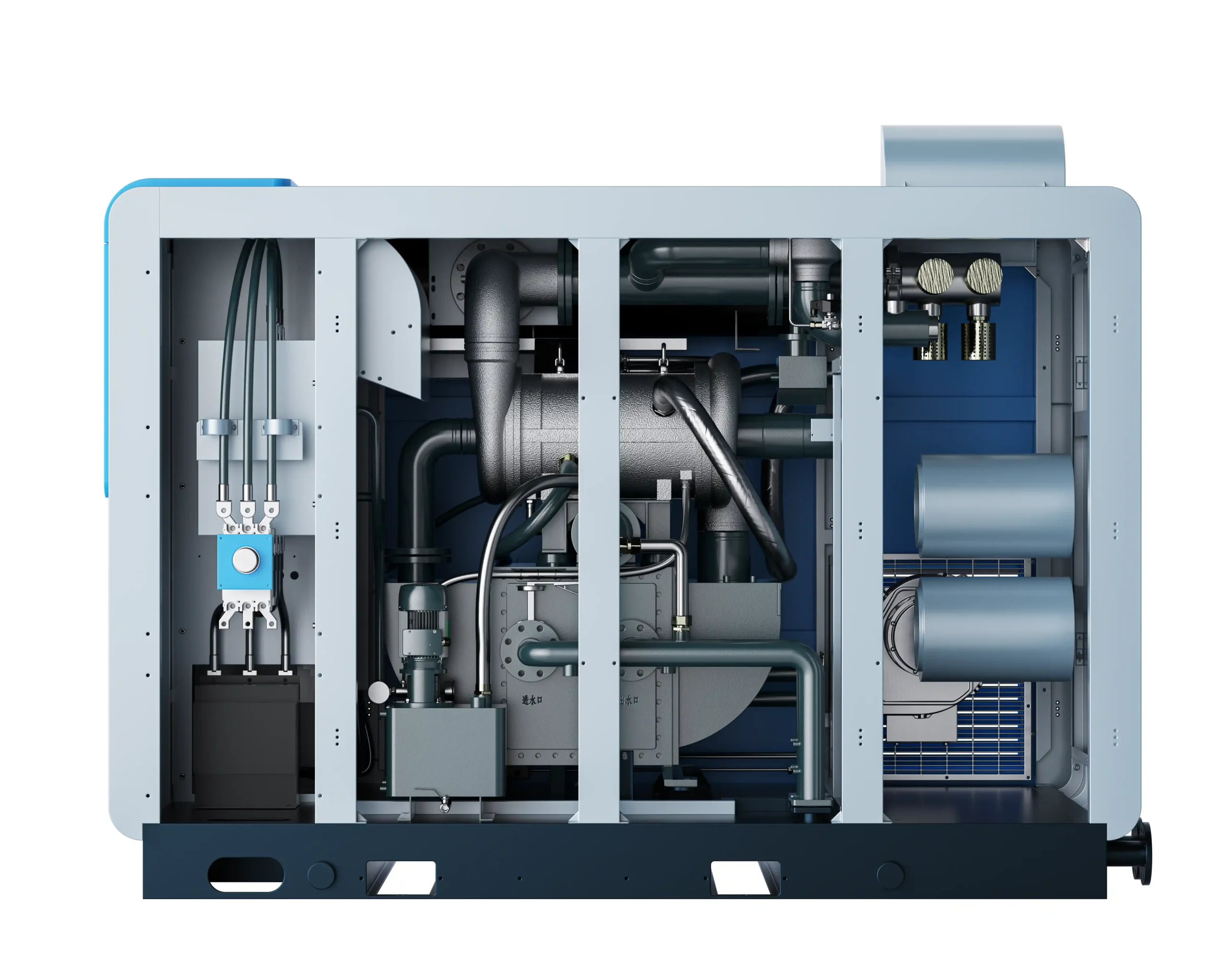

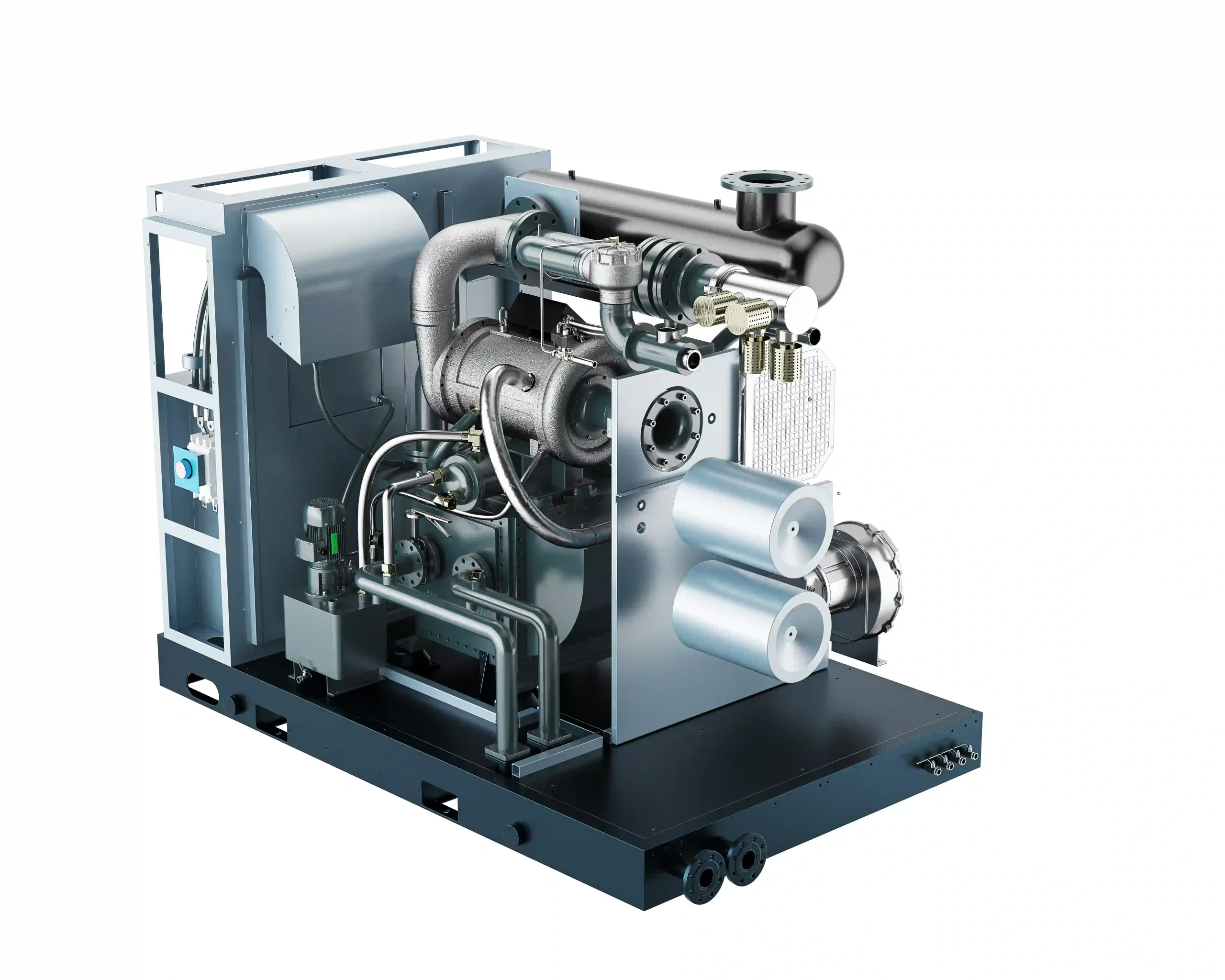

- Air is inhaled from the air inlet

- The air is compressed by the first-stage impeller

- The heat and condensed water are taken away in the first-stage intercooler

- The air is compressed to the final pressure in the second stage

- The air is discharged from the outlet and further cooled by the aftercooler before entering the user system

- The active magnetic bearing system is the core of the magnetic levitation air compressor.

- The motor rotor is fixed between two radial magnetic bearings and a thrust bearing.

- The position of the rotor is detected by the position sensor, and the signal is fed back to the main controller.

- Signal acquisition and real-time correction more than 10,000 times per second ensure stable operation of the rotor.

- Customized low-pressure drop integrated water cooler.

- Built-in steam-water separation filter screen effectively separates moisture from compressed air.

- The internal structure is that water flows inside the pipe and gas flows outside the pipe. The cooling water pipe is evenly wrapped by aluminum fins to increase the heat exchange effect.

- The intermediate cooler is cooled by external cooling water to make the compression process closer to isothermal compression, significantly improve the air compression efficiency, and enhance the energy saving effect.

- Using self-generation technology, when the power supply is normal, the user side inputs the power supply, and after the inverter is rectified, the motor is driven to rotate at high speed; at the same time, the control system and the magnetic bearing controller are powered to achieve stable suspension and system control of the magnetic bearing.

- When the input side is accidentally powered off, the motor switches to the “power generation” mode, and the rotor continues to rotate at high speed with inertia, cutting the motor stator winding, converting kinetic energy into electrical energy, and continuing to power the control system and the magnetic bearing controller until the rotor stops completely and no longer generates electricity.

- UPS is used to power the control system and the magnetic bearing controller (optional).

- The equipment is connected to the Sazhen cloud platform to achieve.

- Real-time monitoring of parameters.

- View the historical operation status of the equipment.

- It can make statistics of operation reports and analyze the operation data of the air compressor.

- When the air compressor is about to be maintained, the system will send the relevant information to the manufacturer as soon as possible and contact the user for maintenance.

- Parameters and start-stop control can be modified remotely through the mobile phone to improve work efficiency.

- The human-machine interface adopts a 10-inch touch screen.

- A self-developed special magnetic levitation air compressor control system.

- The control interface is clear and easy to understand, one-button start, touch screen operation, simple and fast.

- The interface displays various parameters, and the data is monitored in real time to provide a guarantee for the reliable operation of the equipment.

- It adopts water-cooled inverter, focusing on high frequency, with a carrier of up to 15kHz and an output frequency of up to 1200Hz.

- High-performance PG-free vector control technology, good parameter adaptability, high control performance, low output harmonics, and low motor heating.

- It can realize self-learning function, one-button identification of motor parameters and control parameters, and reduce the difficulty of debugging.

- The speed control accuracy is within ±0.2%, and it can withstand higher overload capacity.

NO.1

NO.2

NO.3

NO.4

NO.5

NO.6

NO.7

NO.8

Application fields:

- Adopting advanced core technologies such as magnetic suspension bearings, three-dimensional flow turbines, high-speed permanent magnet synchronous motors, high-speed variable frequency speed regulation, and intelligent monitoring and control, it first suspends and then rotates when starting, without friction, no lubrication required, the turbine and rotor are directly connected, and the transmission is zero loss. The noise is as low as 80 decibels, and it is widely used in sewage treatment, aquaculture, steel, cement, food, brewing, textiles, petrochemicals and other fields.

CH-120A-400A

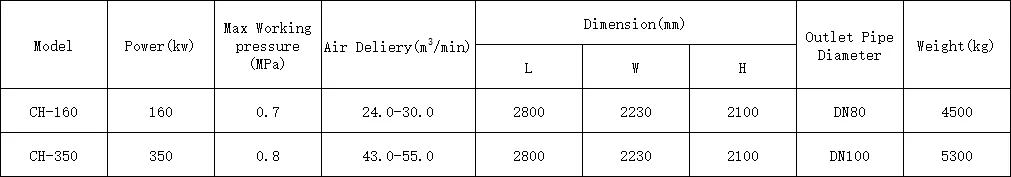

CH-160A-350A

You may Like:

Energy Savings Calculator

Annual Savings

USD 0

* Based on 30% energy efficiency improvement from SEIZE technology

Save up to 30% energy with SEIZE compressors

Explore cutting-edge energy-efficient solutions

English

English

Russia

Russia

France

France

Spain

Spain

Arab

Arab