Magnetic levitation centrifugal energy-saving blower

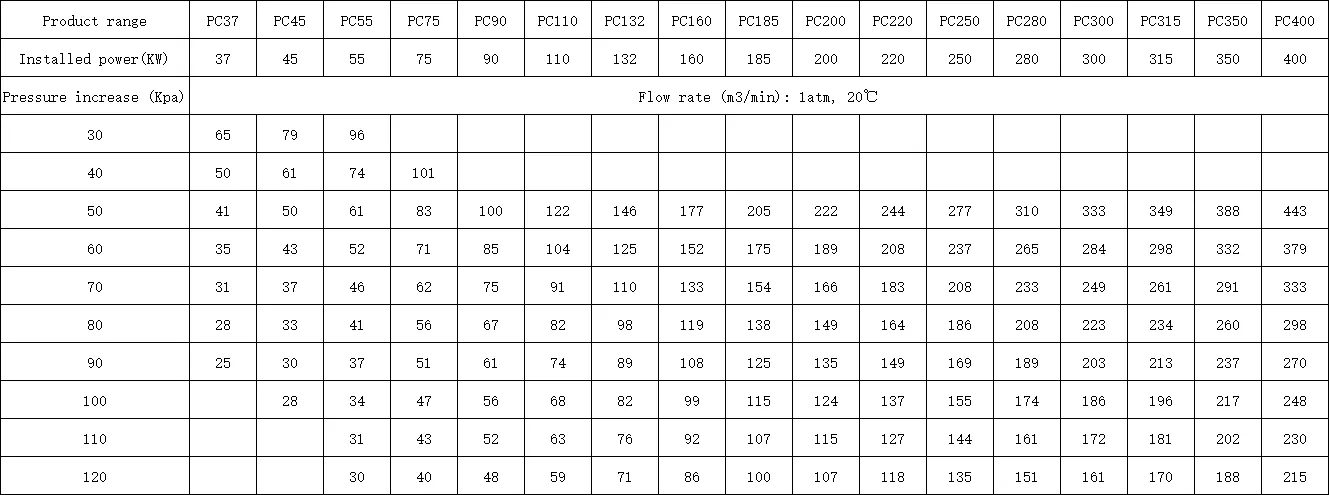

Working Pressure :

0.3-1.2[ bar ]- 4-17[ psig ]

Air Delivery :

821-11179[ cfm ]- 23-313[ m3/min ]

Working Power :

37-400[ kw ]- 50-540[ hp ]

×

- Product Details

- Technical Parameters

Magnetic levitation centrifugal energy-saving blower features:

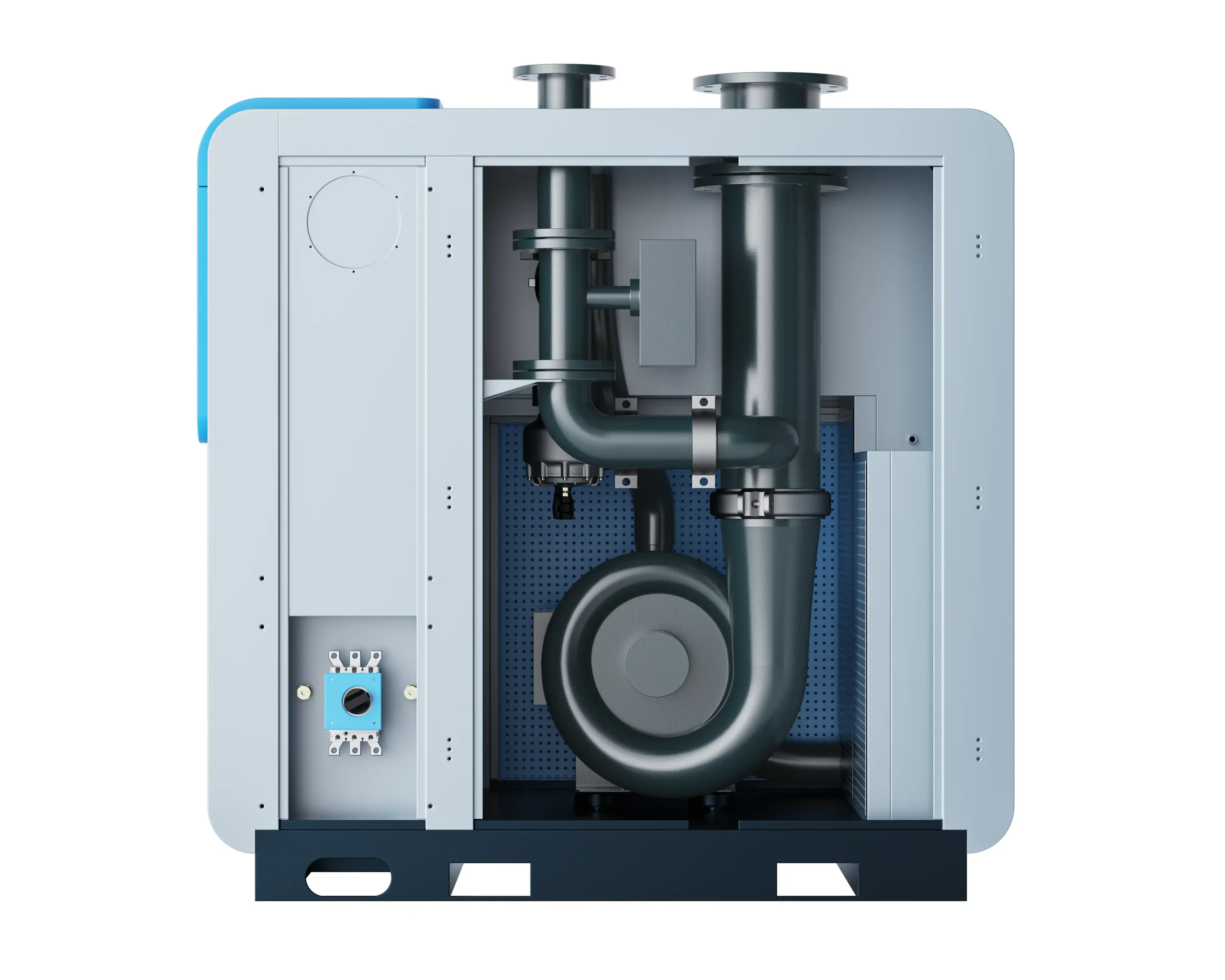

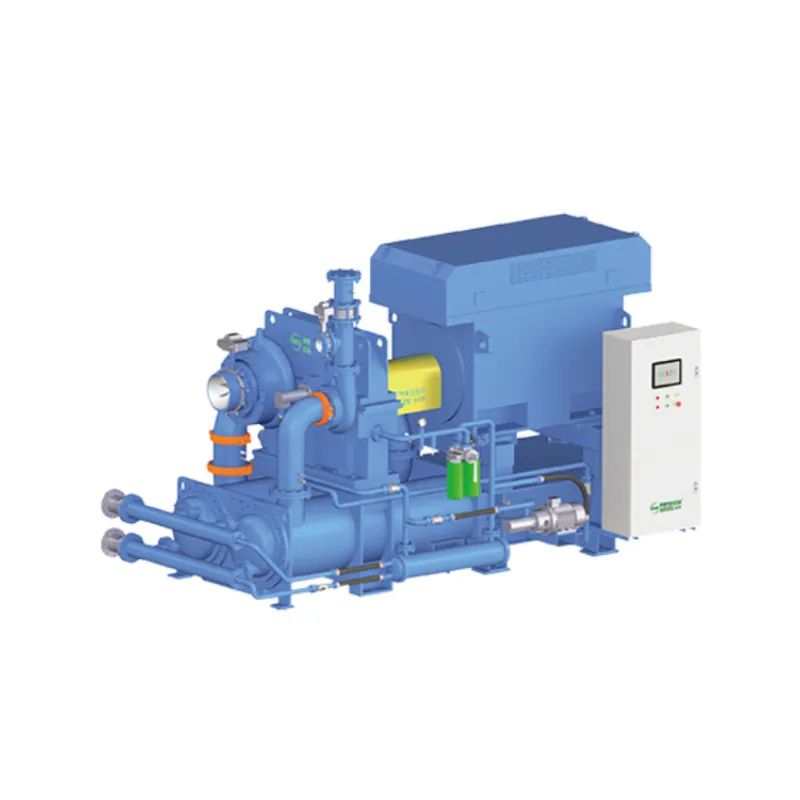

- The magnetic suspension single-stage centrifugal blower belongs to the fourth generation of blowers. It adopts advanced magnetic suspension bearings, high-speed motors, and three-dimensional flow impeller technology. Compared with the previous three generations of blowers, it has the characteristics of energy saving, environmental protection, wide range of air volume adjustment, low noise, low vibration, and easy installation and maintenance.

- The magnetic suspension high-speed centrifugal blower adopts the direct drive structure of the high-speed permanent magnet synchronous motor, and integrates the centrifugal impeller and motor drive into an integrated design. The vibration of the rotating shaft is detected in real time through the built-in displacement sensor, and the collected signal is sent to the magnetic suspension bearing controller for modulation and calculation to generate a control current, and then the current is input into the magnetic bearing coil to generate electromagnetic force, thereby realizing the suspension of the rotating shaft.

- The main function of the permanent magnet synchronous motor is to drive the rotation of the shaft. The frequency converter generates a controllable current, which is input into the motor stator to generate a rotating magnetic field, driving the shaft to rotate at high speed. The impeller that rotates at high speed with the shaft drives the air to enter from the air inlet of the volute. The air reaches the predetermined flow rate and pressure under the guidance and pressurization of the volute, and finally blows out from the air outlet of the volute.

- The magnetic suspension bearing is completely frictionless, reducing the chance of product damage.

- The service life of the fan can reach more than 20 years.

- Simple maintenance, only need to replace the filter regularly.

- No lubrication system is required, saving lubricating oil, cleaning and other costs.

- The motor adopts direct drive, small size, light weight, and space saving.

- Domestic production can ensure the timely supply of spare parts.

- Magnetic suspension control technology is the core technology of magnetic suspension bearings. It uses a high-precision digital controller and realizes stable high-speed suspension of the shaft through high-precision PID control and imbalance compensation algorithm.

- High-efficiency three-dimensional flow backward curved impeller

- Using aviation aluminum alloy material

- More optimized parameter design

- Each impeller is subjected to 115% overspeed test

- Unique micro-spline connection, which can transmit up to 10,000kW of power

- Easy to install and disassemble without damaging parts

- Safety design: redundant design of magnetic suspension bearing power failure protection

- Uninterruptible power supply protection

- Linkage control, automatic protection

- Auxiliary mechanical bearing protection

- 1. Energy saving and high efficiency

The high-efficiency Yongyan motor is directly connected to the high-efficiency three-dimensional fluid impeller, and the transmission structure is greatly simplified, and the energy consumption is reduced by 30%-40% compared with traditional Roots blowers. - 2. Intelligent control

Based on the ECC remote control system independently designed by Sare Electric, it realizes online monitoring of the fan status, intelligent regulation and operation maintenance, and remote debugging. - 3. Low vibration and low noise

In order to ensure the humanized operation requirements, the unique secondary dynamic balancing and operation reduction design and chassis isolation technology are adopted, and the fan noise is controlled at 80dB. - 4. Easy maintenance

The direct-connected high-speed fan does not require a foundation and is easy to install; daily operations only require the replacement of filters, which greatly reduces the maintenance workload.

A

B

C

D

E

F

G

Application field:

- Adopting advanced core technologies such as magnetic suspension bearings, three-dimensional flow turbines, high-speed permanent magnet synchronous motors, high-speed variable frequency speed regulation, and intelligent monitoring and control, it first suspends and then rotates when starting, without friction, no lubrication, direct connection between the turbine and the rotor, and zero transmission loss. The noise is as low as 80 decibels, and it is widely used in sewage treatment, aquaculture, steel, cement, food, brewing, textiles, petrochemicals and other fields.

PC-37A-400A

You may Like:

Energy Savings Calculator

Annual Savings

USD 0

* Based on 30% energy efficiency improvement from SEIZE technology

Save up to 30% energy with SEIZE compressors

Explore cutting-edge energy-efficient solutions

English

English

Russia

Russia

France

France

Spain

Spain

Arab

Arab