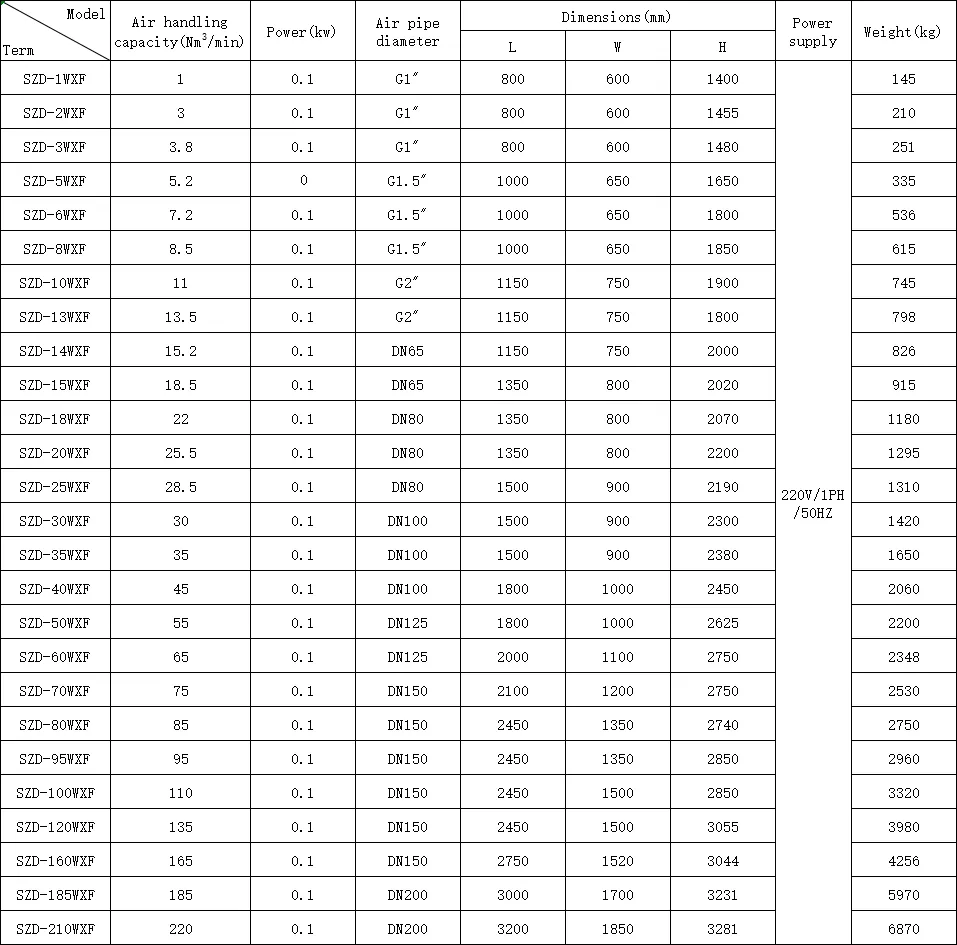

Adsorption dryer

Working Pressure :

0.4-1.0[ Mpa ]Intake oil content :

≤0.01[ ppm ]Air capacity :

1.2-130[ Nm³/min ]

×

- Product Details

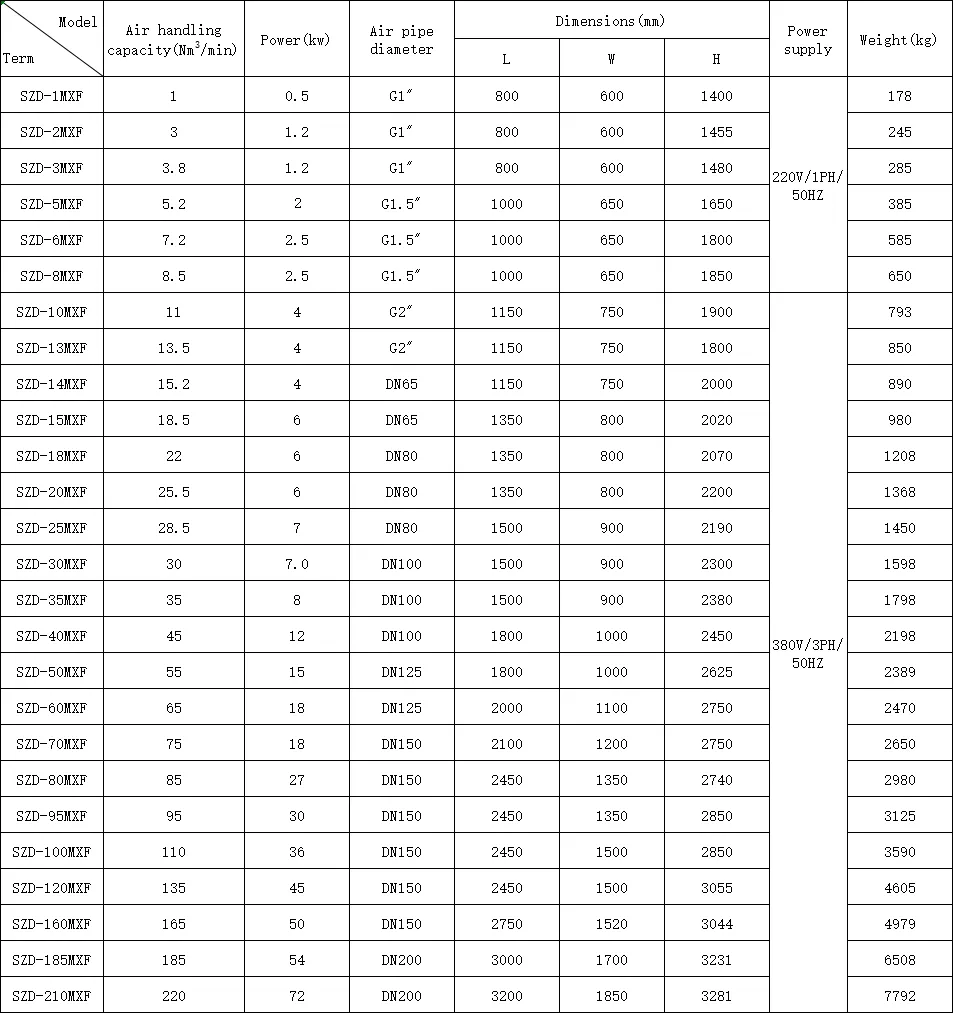

- Technical Parameters

Adsorption dryer features:

- A. Reasonable barrel design ensures that the contact time between compressed air and desiccant is 4.8 seconds, meeting the dew point requirements of finished gas.

- B. 30% desiccant surplus is used to compensate for the natural aging of desiccant and ensure the drying effect.

- C. Large diffuser ensures that the airflow passes through the desiccant layer evenly and eliminates the channel flow phenomenon.

- A. Excellent barrel design saves 95% of the adsorption heat. The stored heat is used to increase the regeneration gas temperature in the regeneration stage, improve the desorption capacity of the equipment, and make the regeneration more thorough.

- B. Drying and regeneration adopt reverse convection, and the effect is better when wet air flows through the dry adsorbent.

- C. The amount of regeneration gas can be adjusted according to the operating load requirements of the dryer.

- A. Appropriate barrel size keeps the flow rate and time of gas through the desiccant layer in a better state, giving full play to the performance of the desiccant.

- B. Reasonable system configuration. Before the airflow enters the barrel, the oil and heavy pollutants contained in the airflow are immediately removed through efficient oil removal treatment to avoid contamination of the desiccant layer.

1. Stable and consistent outlet pressure dew point

2. Regeneration gas loss is less than 12%

3. Long service life of desiccant

4. The equipment uses imported butterfly valves and advanced and reliable microcomputer program controllers, which have the characteristics of automatic timing and automatic switching. The operation is stable and reliable, and is not affected by the power grid, voltage, electric field, etc.

5. The scientific and reasonable switching time design ensures that the outlet air pressure is stable and has no fluctuations.

6. No foundation installation is required, and the installation is simple.

Working principle:

- The heatless regeneration adsorption compressed air dryer uses the unique micropores of the desiccant material itself to adsorb water molecules in the air according to capillary action, and removes the adsorbed moisture according to pressure relief desorption and adsorption residual heat heating. The equipment is generally made into a double-barrel form. Under the control of the program controller, the two barrels work alternately, one barrel adsorbs moisture, and the other barrel desorbs and regenerates, and works continuously and cyclically.

Heatless regeneration adsorption compressed air dryer

Micro-heat regeneration adsorption compressed air dryer

English

English

Russia

Russia

France

France

Spain

Spain

Arab

Arab